| Input | Main Circuit Power Supply | |

| Rated frequency | 50Hz/60Hz (±10%) | |

| Rated voltage |

AC 3 phase 3kV, 6kV, 10kV(10%) |

|

| Power factor | ﹥0.96(20%-100% rated rotation speed) | |

| Control Circuit Power Supply | ||

| Frequency | 50Hz/60Hz (±10%) | |

| Voltage | AC 3 phase 380V, 3 phase 4 wire (10%) AC single phase 220V (10%) | |

| Capacity | 1-5kVA(according to the system capacity) | |

| Output | Frequency | 0~120Hz |

| Voltage | 3kV, 6kV, 10kV ( or customize as per client’s request) | |

| Current | 25A~800A | |

| Power | 110kW~11000kW | |

| Efficiency | ≥97% (input transformer included) | |

| Overload capacity | 120%: 1 min every 10 min | |

| 150%: 10 seconds | ||

| 180%: immediate protection | ||

| Total harmonic | ﹤2% | |

| Control characteristics | Control method | High performance V/F control, open-loop vector control, closed vector control |

| Modulation technology | Optimized SPWM | |

| Frequency accuracy | Analog input: 0.5% (largest output frequency) | |

| Digital input: 0.1% (set input frequency) | ||

| Frequency setting fraction |

Analog input: 0.05Hz(0-10V/4-20mA) Digital input: 0.01Hz |

|

| Torque boost | Manual setting | |

| Accelerate/decelerate time | 1-3600 seconds( setting as per client’s load request), straight line/curve S mode | |

| Drive control transmission | Optical fiber transmission | |

| Operation features |

Frequency setting |

Analog setting: 0-10V/4-20mA |

| Digital setting: local/remote | ||

| Starting method | Forward/ reversion individually controlled | |

| Stopping method | Freewheel stop/controlled stop | |

| Main operation functions | Fast speed start, instantaneous power failure restart, load torque limit | |

| Frequency hopping, multi-speed operation [ upper limit/ lower limit, start/ stop] frequency setting | ||

| System self-diagnosis, PID control, remote control | ||

| Automatic working/ inverting frequency change( optional), unit intelligent bypass (optional), braking function(optional) | ||

| Digital input | Dry contact: 24 ways( extend available) | |

| Digital output | Dry contact: 16 ways( extend available) | |

| Analog input | 4 ways: 0-10V/4-20mA ( extend available) | |

| Analog output | 2 ways: 0-10V/4-20mA (extend available) | |

| Display function | Touch screen/ PC software monitor system | |

| Protection function |

Over-current, short-circuit, over-voltage, under-voltage, overload, over heat, lack of phase, earthing, communication, response Abnormal power control, transformer over heating, abnormal cooling fan, access control failure |

|

| Structure characteristics | Protection grade | IP30 ( standard, or customize) |

| Cooling method | Force air cooling | |

| Cabinet color | RAL7036(grey, or customize) | |

| Environment Requirement | Working temperature | 0℃~+45℃ |

| Relative humidity | ≤95% (no condensation) | |

| Storage temperature | -20℃~+55℃ | |

| Storage temperature | Indoor (no corrosive gases, flammable gas, oil mist) | |

| Altitude | 0-1000m: 100% load capacity; >1000m: derating operation | |

IDrive series HV/MV VFD adopts power unit series superposition to realize system output part, power transform part, test protection part and control part.

Input side

Direct HV( 3KV~10KV ) input, after voltage reduction and isolation to supply each power unit independently.

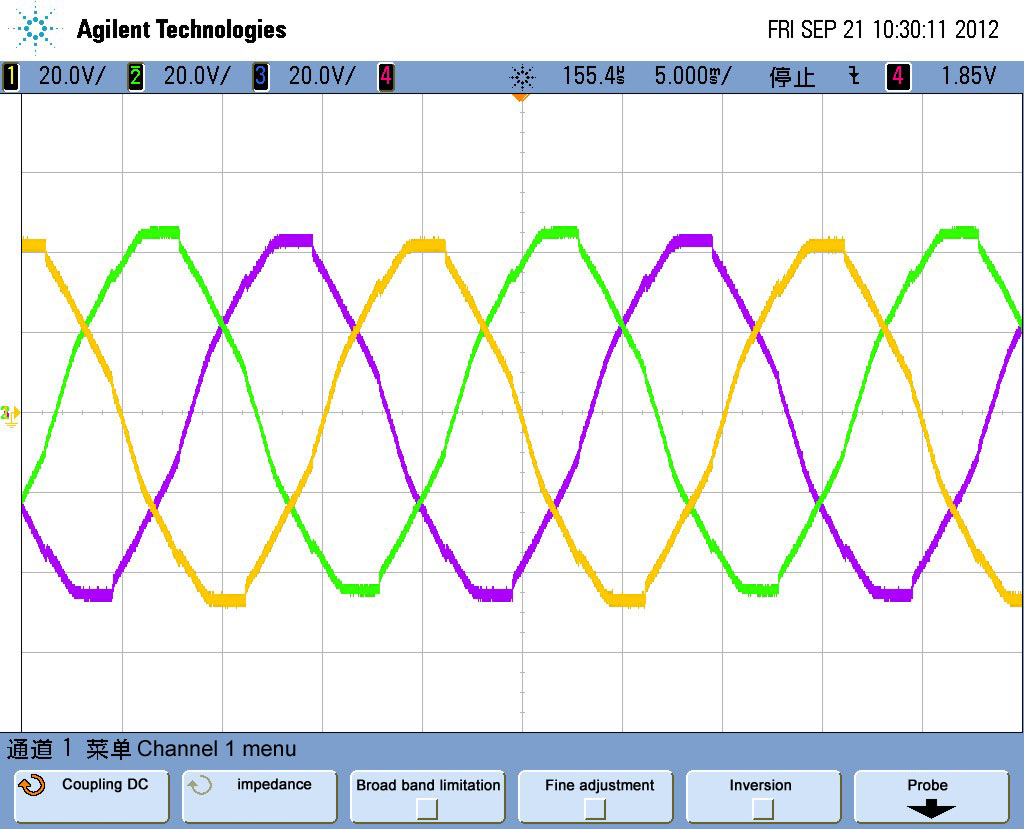

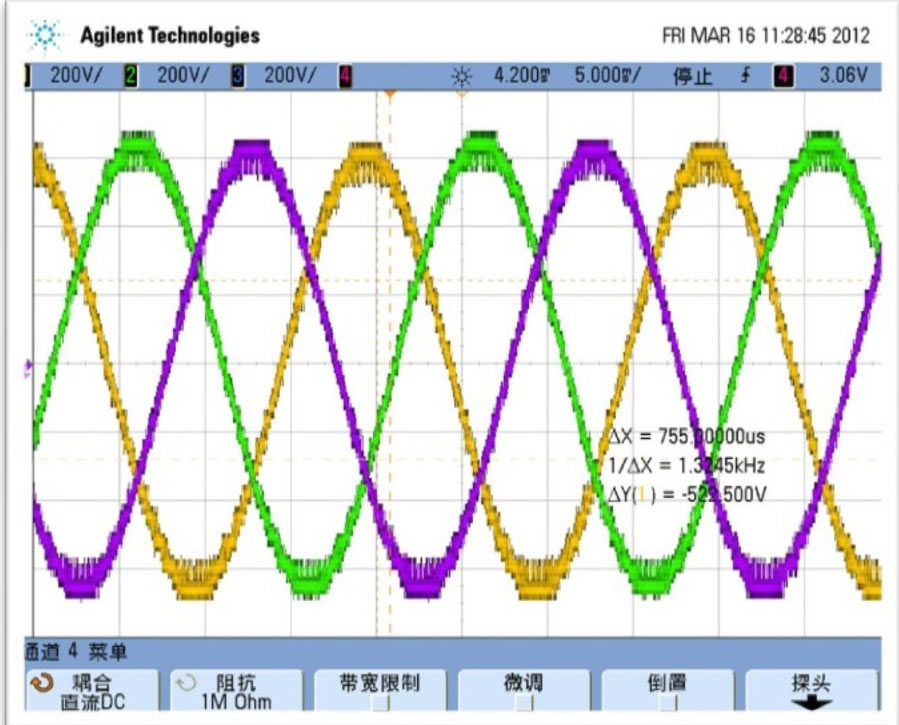

Actual input cable voltage wave

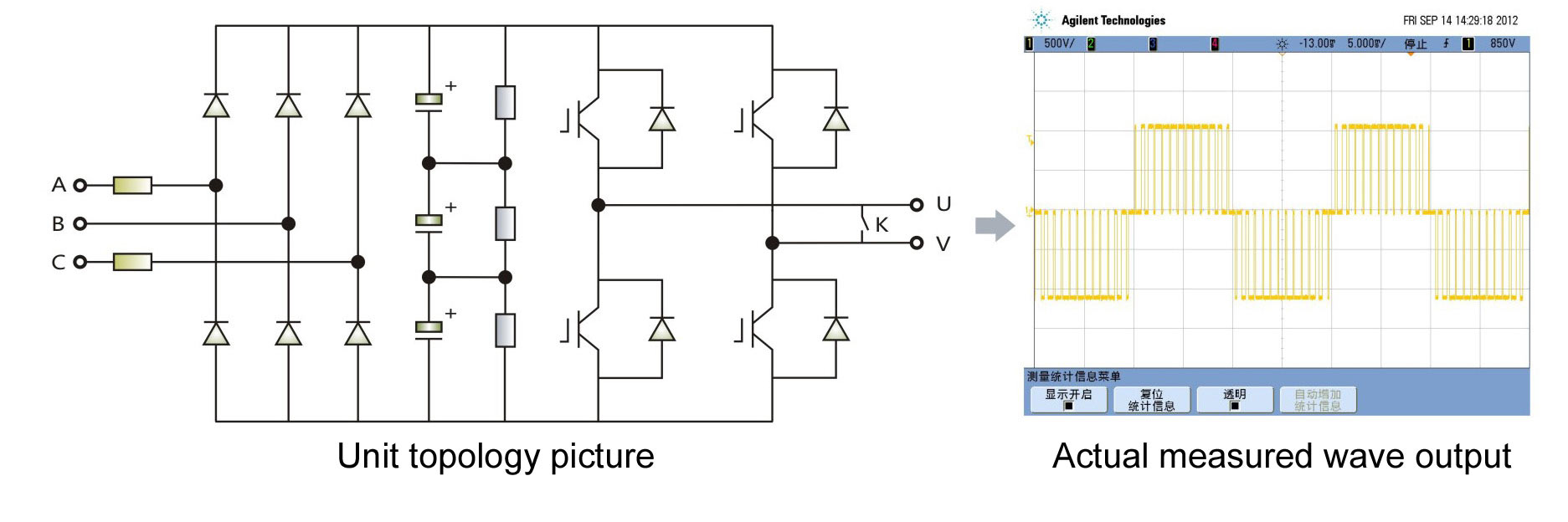

Power unit

AC-DC-AC one side inverter construction. Mainly consisted by rectifier, electrolytic capacitor and IGBT through SPWM controlling IGBT inverter. Input single phase AC, modular design. And every power unit is the same and easy maintenance.

Control part

Consisted by controller, PLC and HMI to realize running, fault alarm solution, indication and backups.

Controller mainly realize system status collecting solution, power init control ect. Of which the communication adopts optical fiber technology between power unit. Low and high voltage can reliable isolated. Fast communication speed. High antijaming capability. Remarkable improved system reliability. PLC mainly realize electric system control and user art-craft on-site standard interface.

HMI mainly realize system itself control interface and status indication. Full Chinese and English and Russian operation interface. Meantime HMI equipped with upper computer software system to realize user end network control.

Output side

Through every power cell superposition and overlay and the use of wave carrier phase shifting technology which can form perfect sine-wave output.

Actual side output cable voltage wave

■ Modular power cell design, maintenance and easy examine and repair.

■ Inverter adopts power cell superposition and overlay technology, mature technology and reliable component.

■ We adopt V/F control sine wave PWM adjustment technology. High accuracy. Fast response and high efficiency.

■ Inverter is suitable for wide range input voltage and international grid conditions. User electric network direct connect. No need any filter device and power factor compensation device.

■ Perfect sine wave output current, no need filter,

■ Output voltage possesses AVR( Automatic voltage regulation ) stabilizer function which is to avoid over-voltage damage motor’s insulation and to lower no-load loss.

■ Torque boost function, boost output voltage and output torque when in low-frequency running.

■ Flying start function, no need to wait motor still to rotate startup function. Tracking process is about 3-5 seconds.

■ Automatic re-start after high voltage failure which is suitable for double power supply changeover grid occasion and grid voltage failure working conditions.

■ Fast dynamic response capability which is fit for harsh requirements for acceleration and deceleration time.

■ Advanced current, voltage limitation function. Fast and safe drive motor.

■ Full colourful HMI which is easy for operation. Powerful function and thorough data.

■ Standard industrial interface and Ethernet interface, compatible standard Modbus, Profibus-DP, TCP/IP agreement which is fit for different on-site network.

■ Compact size, reasonable design which can lower the installation cost.

■ Over-voltage, under-voltage protection

■ Over-load, over-heat protection

■ Short circuit, earthing and over-current protection

■ Phase loss protection

■ Control power has UPS protection.

Chinese

Chinese English

English