Application in the induced draft fan and powder exhaust fan of fire-power plant.

Summary

In fire-power plants, the fans and water pumps are the most important and most power consumption equipments, which often run continuously under the low load or variable load states for a long time. There is a huge energy saving potential if we can reduce the power consumption by adjusting the running speed of those equipments.

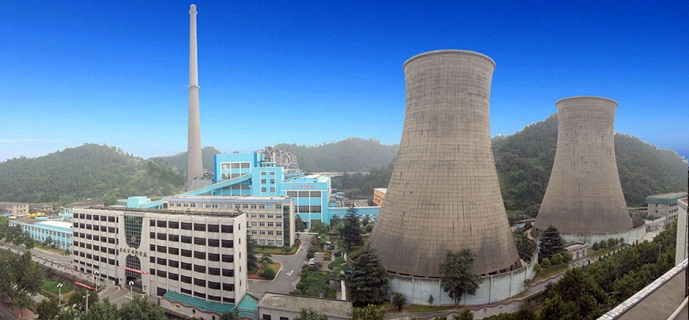

This is a application case of IDrive2000 MV VFD (with automatic bypass function) used in a Hubei Shiyan thermal power plant. Four Drive respectively apply to#1powder exhaust fan, #2 powder exhaust fan, #3 induced draft fan, #4 induced draft fan.

Application

Motor parameters

|

No. |

Parameter |

#1powder exhaust fan |

#2 powder exhaust fan |

#3 induced draft fan |

#4 induced draft fan |

|

1 |

Rated voltage (V) |

6000 |

6000 |

6000 |

6000 |

|

2 |

Rated current (A) |

33.8 |

34.6 |

35.2 |

33.8 |

|

3 |

Rated frequency (Hz) |

50 |

50 |

50 |

50 |

|

4 |

Rated power (kW) |

260 |

260 |

260 |

260 |

|

5 |

Speed (r/min) |

1485 |

1390 |

1500 |

1485 |

|

6 |

Power factor |

0.84 |

0.83 |

0.82 |

0.84 |

Drive Operation parameters:

|

No. |

Motor |

Output frequency (Hz) |

Output current (A) |

Efficiency |

|

1 |

#1powder exhaust fan |

43 |

17.3 |

0.95 |

|

2 |

#2 powder exhaust fan |

35 |

19.5 |

0.98 |

|

3 |

#3 induced draft fan |

35 |

18.5 |

0.98 |

|

4 |

#4 induced draft fan |

40 |

14.5 |

0.96 |

Energy saving calculation (reference P1/P2= (n1/n)³)

1) #1powder exhaust fan,energy saving rate =30.4%

2) #2 powder exhaust fan,energy saving rate =31.35%

3) #3 induced draft fan,energy saving rate =31.35%

4) #4 induced draft fan,energy saving rate =30.76%

According to the actual calculation, the average annual energy saving rate of Hubei Shiyan thermal power plant can reach 30.965%. If the machines run 8226 hours per year, 4 MV Drive can save energy 2649068 KWH.

Chinese

Chinese English

English